Tested at Likuni Girls’ Secondary School in Malawi

MISSION ACCOMPLISHED FOR THIS ENERGY TRANSITION !

Likuni Girls’ Secondary School (LKGSS), near Lilongwe in Malawi, is a boarding school for 600 girls. Until recently, the school used 300 kg of wood a day to cook vegetables and electricity to prepare Nsima (the maize polenta that accompanies all meals in Malawi). Thanks to the implementation of biogas technology, the school has now adopted a sustainable energy approach!

WE’VE COME FULL CIRCLE!

Biogas is a renewable energy source produced by the anaerobic (oxygen-free) decomposition of organic matter such as food waste and manure. This process generates methane-rich gas, used for cooking, and produces a natural organic fertilizer.

The project carried out by Energy Assistance in 2024, with the installation of a biogas system within the school itself, enables green, circular and non-intermittent energy to be produced on site. This technology offers a solution for recovering the school’s organic waste.

Thanks to this technology, the school can not only save on cooking energy and fertilizer costs, but also grow its own food organically. The pupils’ daily meals are now prepared without electricity or wood!

This initiative aims to combat deforestation, improve the school’s energy self-sufficiency (circular economy) and waste management, and reduce its carbon footprint.

BIOGAS BENEFITS

🔥 Free & clean cooking gas

🌿 Free & natural fertilizer

🌾 Improved energy self-sufficiency

♻️ Waste management and promotion of the circular economy

🌍 Reduction of carbon footprint

🌳 Fight against deforestation

For the school cook, the transition to biogas has been a real improvement in his working conditions. Previously, he had to breathe in the noxious smoke from burning wood on a daily basis, which posed health risks. Now, thanks to biogas, he can cook in a healthy environment, improving his well-being and quality of life while continuing to prepare nutritious meals for the young boarders.

IN PRACTICE …

The school has over 20 cows producing some 530 kg of dung per day. It also collects almost 200 kg of organic waste per day (vegetable food scraps, corn bran, etc.). The school also has an adequate water supply for biomass preparation, with a 50,000-liter tank.

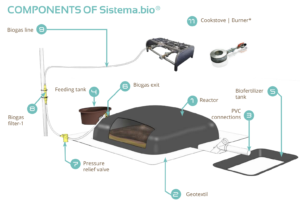

The biomass used as raw material is a mixture composed of 1/3 organic waste (cow dung or other) and 2/3 water. This mixture is introduced into the digester by gravity, and the gas produced by fermentation emerges naturally from the top of the digester, is filtered and directed to the cooking stations in the kitchen, and the fertilizer is collected at the digester outlet.

Want to see how it works? 👉 Vidéo link

EXCELLENT COLLABORATION

Our warmest thanks go to Geneviève Raoult, Sarah Ouziaux and Michael di Marino, Energy Assistance volunteers, for their dedication and enthusiasm.

Many thanks also to Sister Amelia Nyendwa, school principal, for her exemplary commitment to this energy transition, and to Mphatso Elizabeth Gama and Clément Kandodo of EcoGen for their excellent collaboration.